Weather greatly impacts epoxy flooring application. Temperature affects epoxy viscosity; aim for 50-90°F. High temperature speeds curing, but may cause issues. Cold weather slows curing. Humidity influences adhesion and curing; maintain 40-60%. Moisture problems affect adhesion. Delamination risks arise from excessive moisture. Control humidity levels with dehumidifiers. High and low humidity affect adhesion. Choose epoxy resistant to local temperatures. Proper surface prep is vital. Regular maintenance and inspection are key. Each factor plays a role in epoxy success, ensuring durability and longevity.

Temperature: Impact on Epoxy Application

When applying epoxy flooring, the temperature plays a crucial role in determining the success of the application. Temperature affects the viscosity of the epoxy resin, impacting its flow and leveling properties. For optimal results, the ideal temperature range for applying epoxy is typically between 50°F and 90°F.

If the temperature is too low, below 50°F, the epoxy may become too thick, making it difficult to spread evenly. This can result in a rough finish with poor adhesion to the substrate.

On the other hand, if the temperature is too high, above 90°F, the epoxy may cure too quickly, leading to issues such as bubbling, cracking, or an uneven surface.

To ensure the temperature is within the recommended range, it’s essential to monitor both the ambient temperature of the environment and the temperature of the epoxy components before mixing them.

If the temperature is outside the optimal range, consider using heaters or fans to regulate the temperature in the application area.

Humidity Levels: Considerations for Epoxy

Maintaining appropriate humidity levels is essential when applying epoxy flooring to ensure optimal adhesion and curing. Humidity refers to the amount of moisture present in the air, and it plays a crucial role in the epoxy application process.

High humidity levels can negatively impact the curing process, leading to issues such as bubbling, poor adhesion, and a weakened final finish. On the other hand, low humidity levels can cause the epoxy to cure too quickly, resulting in a brittle and uneven surface.

To achieve the best results when applying epoxy flooring, aim for a humidity level of around 40-60%. This range provides the ideal conditions for the epoxy to cure properly and form a strong bond with the substrate. To control humidity levels during application, consider using a dehumidifier or humidifier as needed. Additionally, ensure proper ventilation in the workspace to prevent moisture buildup.

Before starting the epoxy application process, it’s crucial to measure the humidity levels in the environment where the flooring will be installed. By taking the necessary steps to maintain optimal humidity levels, you can enhance the overall quality and durability of your epoxy flooring project.

Effects of Heat on Epoxy Flooring

To ensure the longevity and performance of your epoxy flooring, understanding how heat affects its durability is crucial. High temperatures can have a significant impact on epoxy flooring applications. One key consideration is the curing process of the epoxy. Excessive heat can accelerate the curing time, leading to issues such as bubbling, uneven finishes, or a shortened pot life. It’s essential to monitor the ambient temperature and ensure it falls within the recommended range for the epoxy product being used.

Moreover, prolonged exposure to heat can also affect the overall strength and resilience of the epoxy flooring. High temperatures can cause the epoxy to soften, potentially leading to scratches, dents, or an overall decrease in durability. In extreme cases, excessive heat can even cause the epoxy to delaminate from the substrate, compromising the integrity of the flooring system.

To mitigate the effects of heat on epoxy flooring, consider applying the coating during cooler times of the day or in controlled environments with adequate ventilation and climate control. Additionally, choosing epoxy products specifically designed to withstand high temperatures can help maintain the longevity and performance of your flooring system.

Cold Weather Challenges for Epoxy

When it comes to applying epoxy flooring in cold weather, you need to consider how temperature impacts the curing process. Cold weather can slow down the curing time of epoxy, leading to potential issues with proper hardening.

Additionally, moisture problems can arise in colder conditions, affecting the adhesion and overall quality of the epoxy application.

Temperature Impact on Epoxy

Cold temperatures can significantly impact the application and performance of epoxy flooring. When applying epoxy in cold weather, the material becomes thicker and more challenging to work with. The cold can cause the epoxy to cure more slowly, leading to a longer drying time and potentially affecting the final finish.

In cold conditions, epoxy may not adhere properly to the substrate, resulting in poor bonding and a weaker overall finish. Cold weather can also cause issues with the epoxy’s ability to self-level, leading to uneven surfaces and an unprofessional appearance.

To combat the challenges of cold weather when working with epoxy, consider using a specialized cold-weather epoxy formulation. These products are designed to perform better in lower temperatures, ensuring proper curing and adhesion even in chilly conditions.

It’s crucial to monitor both the ambient temperature and the temperature of the substrate before, during, and after epoxy application in cold weather. Taking these precautions can help you achieve a successful epoxy flooring installation despite the challenges posed by low temperatures.

Cold Weather Curing

Curing epoxy in cold weather presents unique challenges that require careful attention to ensure a successful application. When temperatures drop, epoxy takes longer to cure, impacting its ability to properly adhere to the surface.

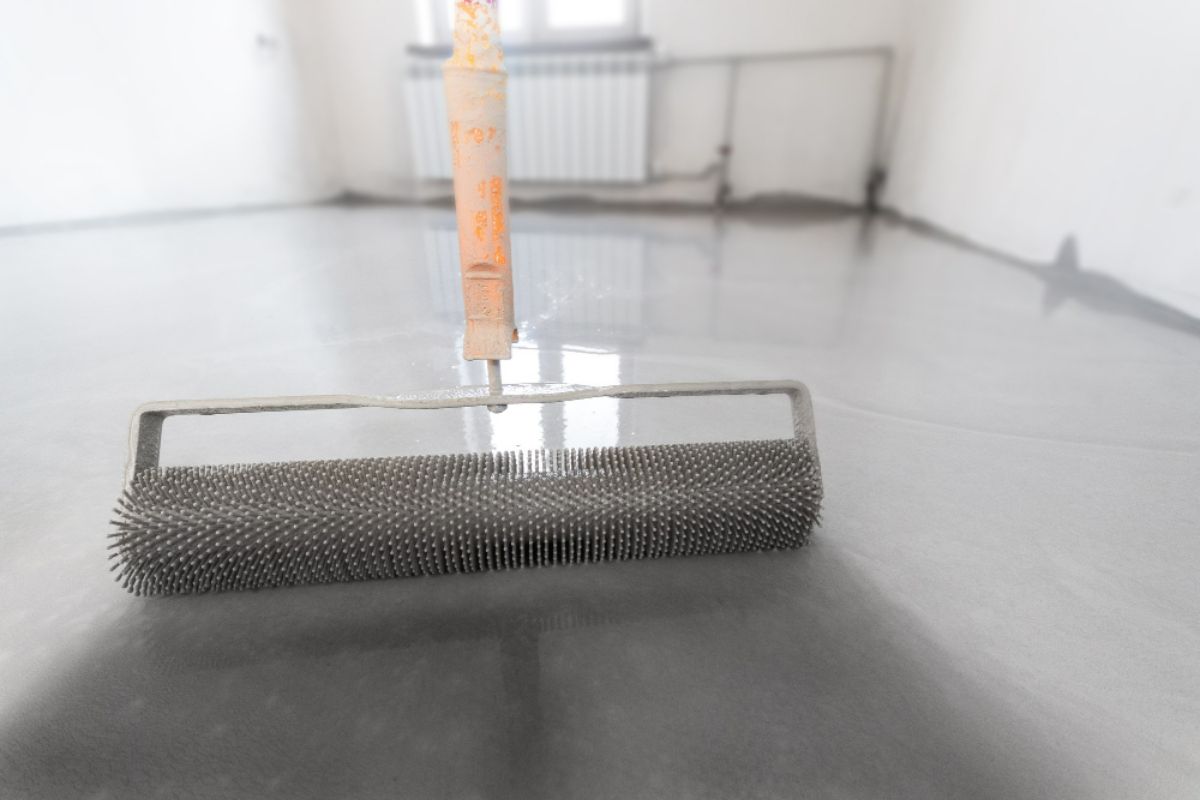

In cold weather, epoxy becomes thicker, making it harder to spread evenly and creating potential issues with self-leveling. To combat this, it’s essential to warm the epoxy before application, either by storing it in a heated room or using a heat gun to lightly warm the material.

Additionally, curing times are significantly extended in cold temperatures, sometimes doubling or even tripling the usual time. This prolonged curing period means that the floor must be protected from foot traffic or other activities for an extended duration to prevent damage to the epoxy surface.

It’s crucial to follow manufacturer guidelines for curing times and ensure that the environment remains at the recommended temperature throughout the curing process. By addressing these challenges proactively, you can achieve a successful epoxy flooring application even in cold weather conditions.

Moisture Problems in Cold

To ensure a successful epoxy flooring application in cold weather, it’s important to address potential moisture problems that can arise during the process. Cold temperatures can lead to condensation forming on the concrete substrate, creating a barrier that prevents the epoxy from adhering properly. This moisture barrier can result in delamination, bubbles, or an overall weakened bond between the epoxy and the substrate.

In cold weather conditions, it’s crucial to test the concrete surface for moisture content before applying epoxy. Utilizing a moisture meter can help determine if the substrate is dry enough for the epoxy to bond effectively. If moisture is present, using a dehumidifier or heater can help remove excess moisture from the air and concrete surface, ensuring a proper application.

Additionally, choosing epoxy products specifically designed for cold weather applications can help mitigate moisture-related issues. These formulations are engineered to cure effectively in lower temperatures, reducing the risk of moisture-related failures.

Prioritizing proper surface preparation and moisture management is key to overcoming the challenges of moisture problems in cold weather when applying epoxy flooring.

Moisture Content: Epoxy Application Risks

You must be cautious of moisture content when applying epoxy on floors. High moisture levels can lead to the risk of delamination, causing the epoxy to peel off prematurely.

Ensure proper humidity levels are maintained during the application process to achieve a successful and durable epoxy flooring finish.

Moisture and Epoxy

When applying epoxy flooring, it’s crucial to consider the moisture content in the environment to avoid potential risks during the application process. Excessive moisture can lead to adhesion issues, affecting the bond between the epoxy and the substrate. High levels of moisture in the air or on the surface can cause the epoxy to bubble, blister, or peel off prematurely, compromising the overall quality of the flooring.

To prevent these problems, it’s essential to measure the moisture content of the concrete substrate before applying epoxy. You can conduct a simple moisture test by taping a plastic sheet to the floor and checking for condensation after 24 hours. If moisture is present, it’s advisable to address the issue before proceeding with the epoxy application.

Additionally, controlling the humidity levels in the application area and ensuring proper ventilation can help mitigate the risks associated with moisture.

Risk of Delamination

Excessive moisture in the environment poses a significant risk of delamination during the application of epoxy flooring, potentially compromising its adhesion and durability. Delamination occurs when the epoxy layer separates from the substrate, leading to bubbling, cracking, or peeling of the flooring system.

Moisture trapped beneath the epoxy surface creates a barrier that hinders proper adhesion, causing the epoxy to detach from the substrate over time. This detachment not only affects the aesthetics of the flooring but also jeopardizes its structural integrity.

To mitigate the risk of delamination, it’s crucial to assess and control the moisture content of the environment before applying the epoxy. Moisture testing tools can help determine if the substrate has excessive moisture levels that could interfere with the adhesion of the epoxy coating.

Addressing any underlying moisture issues and ensuring proper ventilation during the application process are essential steps to prevent delamination and ensure a durable epoxy flooring system.

Proper Humidity Levels

Maintaining appropriate humidity levels is crucial when considering the risks associated with moisture content during epoxy flooring application. High humidity can lead to issues such as poor adhesion, bubbling, or a hazy appearance in the epoxy finish.

On the other hand, low humidity levels can cause the epoxy to cure too quickly, resulting in a brittle and weak flooring surface.

To ensure a successful epoxy flooring application, it’s recommended to keep the humidity levels between 40-60%. If the humidity is too high, consider using dehumidifiers or ventilation to decrease moisture in the air. Conversely, if the humidity is too low, humidifiers can help increase the moisture levels in the environment.

Before starting the epoxy application process, it’s essential to measure the humidity levels using a hygrometer.

Monitoring and adjusting the humidity levels accordingly will help mitigate the risks associated with moisture content and ensure a durable and long-lasting epoxy flooring finish.

Weatherproofing Epoxy: Tips and Tricks

Enhance the durability of your epoxy flooring by implementing effective weatherproofing techniques. Weatherproofing your epoxy floor is crucial to ensure longevity and prevent damage from external elements.

Here are some tips and tricks to help you weatherproof your epoxy flooring successfully:

Start by thoroughly cleaning the surface before applying the epoxy coating. Any dirt or debris left on the floor can compromise the adhesion of the epoxy and affect its weatherproofing capabilities. Ensure the surface is completely dry before beginning the epoxy application to prevent any moisture-related issues.

Choose a high-quality epoxy resin that’s specifically designed to withstand your local climate conditions. Some epoxies are formulated to be UV resistant, which is beneficial if your area experiences a lot of sunlight. UV-resistant epoxies can prevent yellowing and fading of the flooring over time.

Consider applying a topcoat or sealer over the epoxy to provide an extra layer of protection. This can further enhance the weatherproofing properties of the flooring and improve its resistance to water, chemicals, and abrasions.

Regularly inspect your epoxy flooring for any signs of wear and tear, especially after extreme weather conditions. Promptly address any damages by applying touch-ups or resealing the floor to maintain its weatherproofing properties.

Curing Time: Weather’s Role in Epoxy

Ensure optimal curing time for your epoxy flooring by understanding how weather conditions play a significant role in the process. The curing time of epoxy is greatly influenced by the weather conditions during and after application. In general, epoxy cures best in moderate temperatures ranging from 60°F to 90°F.

Extreme heat can accelerate the curing process, leading to a faster set time, which may result in a less durable finish. On the other hand, cold temperatures slow down the curing process, prolonging the time it takes for the epoxy to fully harden.

Humidity levels also impact the curing time of epoxy. High humidity can cause issues such as bubbling or cloudiness in the finish, while low humidity can lead to a longer curing time and potential adhesion problems. It’s crucial to check the manufacturer’s recommendations for the ideal temperature and humidity range for curing epoxy.

To ensure a successful epoxy flooring application, monitor the weather conditions before, during, and after the process. Consider using space heaters or fans to regulate the temperature and humidity in the application area if necessary.

Frequently Asked Questions

Can Epoxy Flooring Be Installed Outdoors in All Weather Conditions?

You can install epoxy flooring outdoors in various weather conditions. However, extreme temperatures or humidity may affect the application process and final result. It’s crucial to follow manufacturer guidelines and consider weather factors for successful installation.

How Does Altitude Affect Epoxy Curing Time?

At higher altitudes, epoxy curing time may be affected due to lower air pressure and temperature variations. These factors can slow down the curing process, requiring adjustments in application techniques and timing for optimal results.

Are There Specific Weather Conditions That Can Cause Epoxy Discoloration?

Specific weather conditions, like high humidity or extreme temperatures, can lead to epoxy discoloration. Ensure optimal application by checking moisture levels and avoiding application during rainy or very hot days to prevent discoloration issues.

What Impact Do Strong Winds Have on Epoxy Application?

Strong winds during epoxy application can cause issues like uneven coating, dust contamination, and premature drying. Ensure a sheltered area for work and adjust application techniques to counter wind effects for a successful finish.

Can Extreme Weather Conditions Lead to Epoxy Delamination?

Extreme weather conditions like high humidity or temperature fluctuations can indeed lead to epoxy delamination. It is crucial to monitor and control environmental factors during application to prevent adhesion issues and ensure a successful epoxy flooring outcome.

Conclusion

Remember, when applying epoxy flooring, always consider the weather conditions. Temperature, humidity, heat, cold, and moisture all play a role in the success of your application.

Be sure to take the necessary precautions and follow the recommended guidelines for weatherproofing your epoxy. By paying attention to these factors, you can ensure a smooth and durable finish for your flooring project.

Happy epoxying!