Inspect basement coatings regularly for peeling, cracks, or discoloration to maintain their integrity and appearance. Begin by thoroughly cleaning the surfaces to remove dirt, debris, and any loose particles that could interfere with the repair process. For cracks and holes, use appropriate patching compounds such as acrylic sealants for minor issues or epoxy-based compounds for more significant damage. Apply these solutions carefully, ensuring they blend well with the existing coating to achieve a seamless repair.

Once repairs are complete, it’s essential to protect the restored coating with regular sealant applications. This not only enhances the coating’s durability but also helps prevent future damage. Consider using a high-quality basement sealant that offers resistance to moisture and wear, ensuring your basement remains in optimal condition. Regular maintenance, such as periodic inspections and touch-ups, will prolong the life of your basement coatings. Additionally, controlling the basement environment by using dehumidifiers and ensuring proper ventilation can help minimize the risk of future damage, keeping your basement coatings looking their best for years to come.

For particularly stubborn stains or extensive damage, it may be beneficial to consult with a professional to assess the situation and recommend the best course of action. Professionals can provide specialized solutions and techniques that may not be readily available to homeowners, ensuring a thorough and effective restoration. Investing in professional help can ultimately save time and money by preventing the need for frequent repairs and extending the life of your basement coatings.

Assessing the Basement Coating Damage

To begin assessing the damage to your basement coating, carefully inspect the walls and floors for any signs of peeling, cracking, or discoloration. Start by examining the walls for any areas where the coating has started to peel or bubble. This could indicate water damage or poor adhesion of the initial coating. Cracks in the coating may suggest structural issues or improper application. Take note of any discoloration on the walls or floors, as this could point to mold growth or water seepage.

Next, check for any areas where the coating has worn away, leaving the underlying surface exposed. This could be due to high foot traffic, furniture scraping against the walls, or cleaning methods that are too abrasive. Look for areas where the coating has become dislodged or detached from the walls or floors. These sections will need to be addressed promptly to prevent further damage.

Additionally, inspect the corners and edges of the basement for any signs of damage. These areas are more prone to wear and tear, so they may require special attention during the repair process.

Preparing the Surface for Repair

Begin by thoroughly cleaning the damaged basement coating surfaces to remove any dirt, debris, or contaminants that could hinder the repair process. Use a stiff brush or a pressure washer to scrub the surface and ensure all loose particles are removed. Pay close attention to corners and edges where buildup may be more significant. After cleaning, allow the surface to dry completely before proceeding with any repairs.

Next, inspect the cleaned surface for any cracks, holes, or areas of delamination. Use a putty knife or a similar tool to remove any loose or flaking material. For larger cracks or holes, consider using a concrete patching compound to fill in the damaged areas. Follow the manufacturer’s instructions for mixing and applying the patching material.

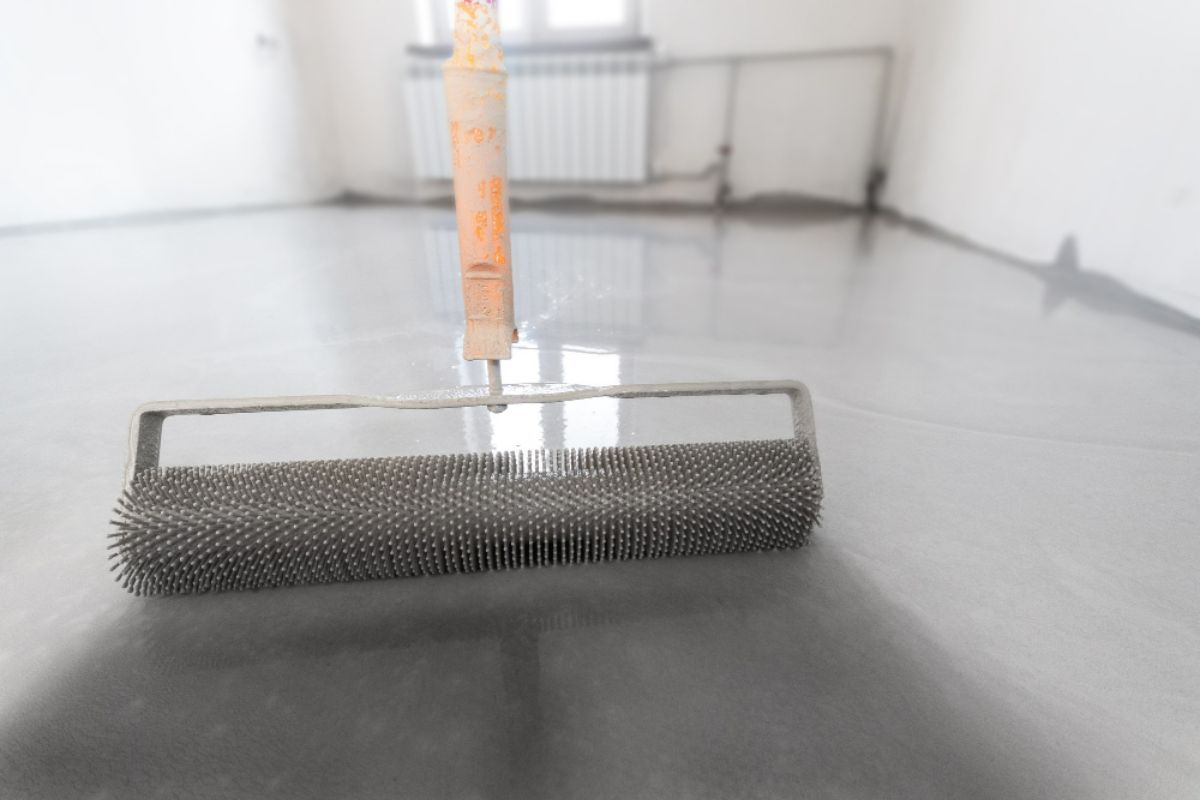

Once the surface is free of debris and any necessary patching has been done, it’s essential to roughen the existing coating with sandpaper or a sander. This step helps create a better bond between the old surface and the new coating. Be sure to remove any dust created during this process before moving on to the next step.

Choosing the Right Repair Materials

Inspecting the cleaned surface for cracks, holes, or areas of delamination will guide you in selecting the appropriate repair materials for your damaged basement coatings.

For small cracks, acrylic sealants are a good choice as they can easily fill in the gaps and provide a smooth surface. These sealants are flexible, which is essential in a basement environment where the foundation can shift slightly over time.

If you have larger cracks or holes, consider using epoxy-based patching compounds. These compounds are strong and durable, ideal for repairing more significant damage. Make sure to follow the manufacturer’s instructions carefully when mixing and applying epoxy products for the best results.

In cases where there’s extensive delamination or peeling of the coating, a concrete resurfacer might be necessary. This material can help restore the surface to its original smoothness and appearance. Concrete resurfacers are typically easy to apply and can provide a fresh new look to your basement floor.

When choosing repair materials, it’s essential to consider the specific needs of your basement coatings. By carefully assessing the damage and selecting the right products, you can effectively restore your basement surfaces and prevent further deterioration.

Applying the Repair Solution

Start by preparing the cleaned surface for application of the chosen repair solution. Ensure that the surface is completely dry before proceeding. If there are any cracks or holes, fill them in with a suitable patching compound and allow it to dry according to the manufacturer’s instructions.

Next, it’s time to apply the repair solution. Follow the directions on the product label carefully to achieve the best results. Use a brush or roller to evenly coat the damaged areas, making sure to blend the repair solution seamlessly with the surrounding coating. Apply multiple thin layers if needed, allowing each coat to dry completely before adding the next.

When applying the repair solution, pay attention to any specific instructions regarding temperature and humidity levels. These factors can affect the drying time and overall performance of the product. Additionally, make sure to work in a well-ventilated area and wear appropriate protective gear, such as gloves and a mask, to avoid inhaling potentially harmful fumes.

After the repair solution has been applied and has fully cured, inspect the coated area to ensure that the repair has been successful. If necessary, touch up any areas that may need additional attention.

Maintaining and Protecting the Coating

To prolong the lifespan of your basement coating, regularly applying a protective sealant is essential. This sealant acts as a barrier against moisture, chemicals, and other potential sources of damage. By maintaining a protective layer, you can prevent wear and tear, ensuring that your basement coating stays in optimal condition for a longer period.

In addition to applying a sealant, it’s crucial to keep your basement coating clean. Regularly sweeping and mopping the surface will help remove dirt, debris, and other substances that could cause abrasions or deterioration over time. Avoid using harsh cleaning chemicals that may strip away the protective sealant or damage the coating itself.

Furthermore, be proactive in addressing any issues that arise. If you notice signs of wear, such as peeling or chipping, take the time to repair these areas promptly. Ignoring small damages can lead to more extensive problems down the line, requiring more extensive repairs.

Lastly, consider implementing preventative measures to safeguard your basement coating. Place rugs or mats in high-traffic areas to reduce friction and protect the surface. Avoid dragging heavy furniture or sharp objects across the coating, as these can cause scratches or gouges that compromise the integrity of the sealant.

Frequently Asked Questions

Can I Repair Basement Coating Damage Without Professional Help?

You can repair basement coating damage without professional help by assessing the extent of the damage, cleaning the area thoroughly, applying a suitable repair product, and allowing it to cure properly before using the area again.

How Long Should I Wait Before Walking on the Repaired Surface?

You should wait at least 24 hours before walking on the repaired surface. This time allows the coating to fully cure and bond, ensuring a durable finish. Rushing this step could compromise the repair’s effectiveness and longevity.

What Is the Average Lifespan of Repaired Basement Coatings?

On average, repaired basement coatings last around 5-10 years with proper maintenance. Factors like quality of repair, type of coating, and usage can affect lifespan. Regular inspections and touch-ups help extend longevity.

Are There Any Specific Weather Conditions to Avoid During Repairs?

Avoid extreme weather conditions like heavy rain, high humidity, or freezing temperatures during repairs. These conditions can affect the effectiveness of your efforts and the longevity of the repair work. Stick to moderate weather for best results.

Can I Apply a New Coating Over an Existing Repaired One?

Yes, you can apply a new coating over a properly repaired existing one. Ensure the surface is clean and prepped for adhesion. Follow manufacturer guidelines for compatibility and application. A well-executed repair sets the stage for a successful recoating.

Conclusion

In conclusion, by following these tips for repairing and restoring damaged basement coatings, you can effectively address any issues and prolong the life of your coating.

Remember to properly assess the damage, prepare the surface, choose the right repair materials, apply the solution carefully, and maintain and protect the coating for long-lasting results.

With the right approach, your basement coating can be restored to its original condition in no time.